Tin Tức

Tool And Die Machining Corp

Tool And Die Machining Corp

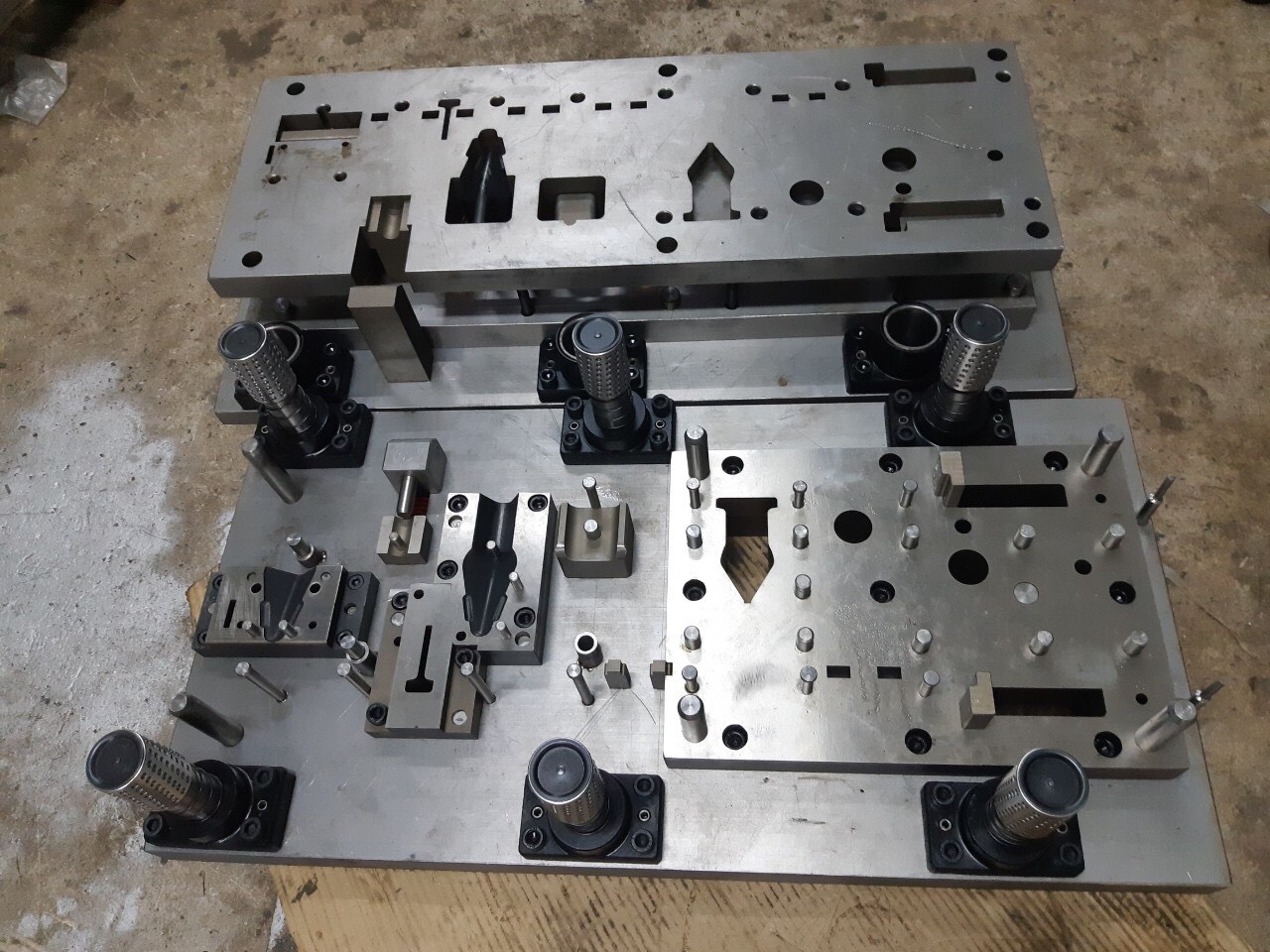

Tool And Die Machining Corp Tri Viet is a company specializing in mold processing, metal stamping and manufacturing high quality mechanical products. With over 15 years of experience and reputation in the industry, Tri Viet has become one of the leading units in the field of mechanical processing in Vietnam.

The company puts customer care first, committed to providing high quality, diverse and flexible services to meet all customer requirements. Tri Viet owns a team of lucky engineers and technicians with high professional skills, creativity and enthusiasm in their work.

Tool And Die Machining Corp Tri Viet provides many services and products, including die design and manufacturing, precision mechanical machining, machinery component assembly and many other mechanical products. The company is committed to using modern technology and advanced manufacturing processes to ensure product quality and customer satisfaction.

With a working philosophy of professionalism, prestige and responsibility, Tool And Die Machining Corp Tri Viet constantly strives to become a reliable and trustworthy partner for all customers, accompanying them on the path to success. and sustainable development.

Benefits of continuous stamping molds in production

Precision: Precision continuous stamping molds help create metal parts with high precision and uniformity, ensuring accuracy in size and shape.

Increased productivity: The precision progressive die process increases production productivity, reduces production time and optimizes workflow.

Material savings: Precision progressive dies help optimize material usage, reduce waste and save production costs.

Product diversity: The precision continuous die stamping process allows the production of a variety of complex and high-quality metal products.

Labor safety: Precision continuous stamping molds can be automated, reducing the risk of accidents for workers and creating safe working conditions.

How to use continuous stamping dies effectively

To use progressive dies effectively in your metal manufacturing process, consider the following steps:

Select and design a suitable stamping mold: Select and design a continuous stamping mold to suit the product to be produced, including evaluating size, shape, product quantity, materials and requirements. other techniques.

Periodically check and maintain dies: Make sure dies are checked and maintained periodically to ensure stable and accurate operation.

Adjust appropriate parameters and pressure: Adjust parameters and pressure of the die to meet production requirements, while reducing the risk of damage and increasing production efficiency.

Track the production process: Track the production process by monitoring the die process to ensure product quality and accuracy.

Regular maintenance and cleaning of dies: Maintain and clean dies regularly to avoid problems or damage and maintain high performance.

Employee training and guidance: Ensure employees have sufficient skills and knowledge to use progressive dies safely and effectively.

By applying the above measures, the use of continuous stamping dies will become effective, helping to improve product quality, increase productivity and save costs in the industrial production process.

Hotline 0908.286.507 | Consulting on design molds - continuous stamping molds

TRI VIET MECHANICAL - ELECTRICAL CO., LTD - With the motto: "Adding value together with you" - Tri Viet Electric is pleased to welcome and cooperate with all customers in the future.

Address: III-14 Street No. 13, Tan Binh Industrial Park, Tan Phu District, HCMC

Hotline: 0908.286.507

Email: uttn066@yahoo.com.vn

Website: http://khuondap.vn/

Bài viết khác:

Các bài viết khác

- Đặc Tính Ứng Dụng Của Khuôn Dập Liên Hoàn - Khuôn Dập Liên Tục

- Khuôn Đột Dập

- Công Ty Khuôn Dập Liên Hoàn Theo Yêu Cầu

- Gia Công Sản Phẩm Dập Tấm | Trí Việt

- Khuôn Dập Nguội

- Khuôn Dập Vuốt Là Gì ? Cấu Tạo Và Đặc Điểm

- Nhận Đột Dập Kim Loại Giá Rẻ

- Kinh Nghiệm Thiết Kế Khuôn Dập - Chế Tạo Khuôn Dập

- Khuôn Đột Dập Liên Hoàn Trí Việt

- Thiết Kế, Sản Xuất Và Bảo Trì Khuôn Dập Liên Hoàn