Tin Tức

Tool And Die Manufacturing Company | Tri Viet Mechanical Company

Tool And Die Manufacturing Company | Tri Viet Mechanical Company

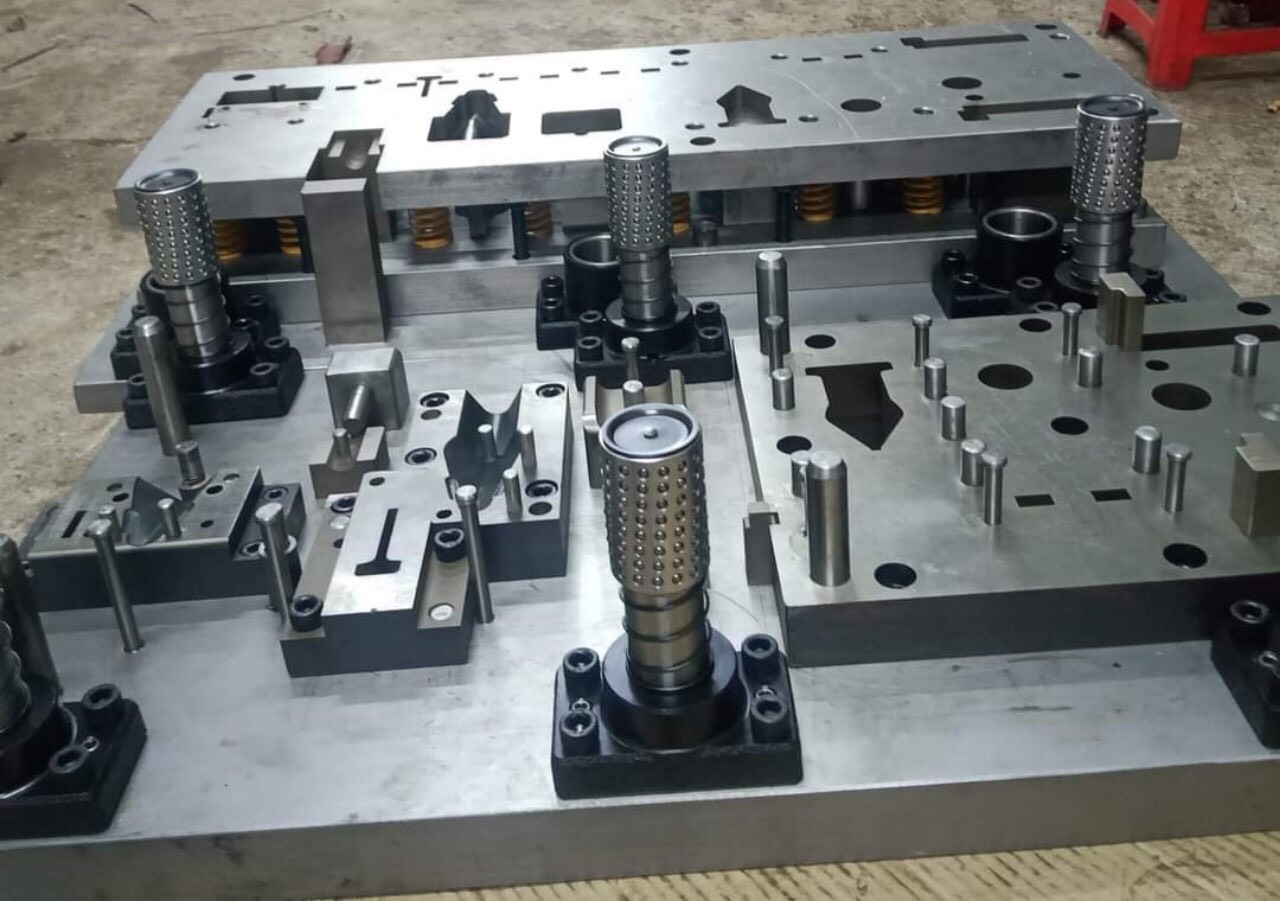

A tool and die manufacturing company specializes in the design, development, and production of tools, dies, and related components used in various manufacturing processes. Tri Viet Mechanical Company typically work closely with industries such as automotive, aerospace, electronics, appliance manufacturing, and more. They play a crucial role in creating the tooling necessary for the production of precision parts and components.

What are the types of tools and dies manufacturing companies have?

Manufacturing companies that specialize in tool and die production typically have various types of tools and dies in their repertoire. Here are some common types:

Progressive Dies: Progressive dies are used for high-volume production of complex parts. They consist of multiple stations with different cutting and forming operations. The material progresses through each station, with the final part being formed at the last station.

Transfer Dies: Transfer dies are used when the part requires multiple operations that cannot be accomplished in a single press stroke. The part is transferred from one station to another using a mechanical transfer system.

Forming Dies: Forming dies are used to shape the material through processes like bending, stretching, or drawing. They are commonly used in industries such as automotive, aerospace, and appliance manufacturing.

Blanking Dies: Blanking dies are used to cut flat shapes from sheet metal or other materials. They create the outline of the part without any additional forming operations.

Piercing Dies: Piercing dies are used to create holes or openings in the material. They can be designed to create simple round holes or more complex shapes.

Extrusion Dies: Extrusion dies are used in the extrusion process, where a material is forced through a die to create a continuous profile or shape. This process is commonly used in the production of plastic, rubber, or metal products.

Drawing Dies: Drawing dies are used in the process of drawing, where a flat sheet or wire is pulled through the die to reduce its cross-section and elongate it into a desired shape.

Embossing Dies: Embossing dies are used to create raised or recessed designs on the surface of the material. They are commonly used for decorative or branding purposes.

Coining Dies: Coining dies are used to create highly precise and detailed features, such as logos or text, on coins or medals. They require extremely tight tolerances to achieve the desired level of detail.

These are just a few examples of the types of tools and dies that manufacturing companies may have. The specific types and complexity of tools and dies depend on the industry, application, and production requirements of the company.

Technical requirements of tool and die

The technical requirements of tool and die manufacturing can vary depending on the specific application and industry. However, here are some common technical requirements:

Material Selection: Tool and die materials should have high strength, hardness, wear resistance, and toughness to withstand the stresses and strains encountered during the manufacturing process. Common materials used include tool steels, carbide, and various alloys.

Dimensional Accuracy: Tools and dies must be manufactured to precise dimensions and tolerances to ensure the proper fit and functionality of the final product. The dimensional accuracy of the tooling is critical for producing parts that meet the required specifications.

Surface Finish: The surface finish of the tool and die is important for achieving the desired surface quality of the final product. A smooth and defect-free surface helps reduce friction, improve part release, and enhance the overall appearance.

Hardness and Wear Resistance: Tool and die components, especially those in contact with the workpiece, need to have high hardness and wear resistance to withstand the repetitive forces and abrasive wear encountered during the manufacturing process. Heat treatment processes like hardening and tempering are often employed to achieve the desired hardness.

Heat Dissipation: Efficient heat dissipation is crucial to prevent overheating and thermal deformation of the tool and die. Proper design considerations, such as cooling channels or heat sinks, are necessary to manage heat buildup during the manufacturing process.

Tooling Precision and Alignment: Tools and dies must be precisely machined and aligned to ensure accurate and consistent production. Proper alignment of tooling components is critical for achieving tight tolerances and minimizing part variations.

Tool Maintenance and Repair: Tool and die designs should facilitate ease of maintenance and repair. Components that are prone to wear or damage should be easily accessible and replaceable to minimize downtime and production interruptions.

Tool Life and Durability: Tools and dies should have sufficient durability and resistance to fatigue, allowing them to withstand the expected number of cycles during their service life. Proper material selection, heat treatment, and maintenance practices contribute to extending tool life.

Compatibility and Interchangeability: In industries with interchangeable tooling, compatibility and interchangeability of tooling components are essential. Standardization of sizes, mounting systems, and interfaces facilitates easy interchangeability and reduces production costs.

These technical requirements ensure that the tools and dies meet the necessary performance, precision, and durability standards required for efficient and reliable manufacturing processes.

Crafting Consistent and Precise Metal Components

Crafting consistent and precise metal components requires careful attention to various factors throughout the manufacturing process. Here are some key considerations:

Design and Engineering: A well-designed component starts with detailed engineering and design. Clear specifications, accurate drawings, and precise measurements are essential to ensure consistency and precision in the final product.

Material Selection: Choosing the right material for the metal component is crucial. Factors such as strength, hardness, corrosion resistance, and machinability need to be considered based on the component's intended use. Proper material selection contributes to the desired properties and dimensional stability of the final product.

Tooling and Equipment: Utilizing high-quality tooling and equipment is essential for consistent and precise metal component production. Precision machinery, such as CNC machines, lathes, milling machines, and grinding equipment, helps achieve accurate shapes, dimensions, and surface finishes.

Quality Control: Implementing robust quality control measures throughout the manufacturing process is vital. Regular inspections, measurements, and tests ensure that the components meet the specified tolerances and quality standards. This may involve the use of gauges, calipers, coordinate measuring machines (CMMs), or other inspection tools.

Machining Techniques: Employing precise machining techniques is critical for consistent and precise metal component production. This includes factors such as cutting speeds, feeds, tool paths, and tool selection. Proper machining techniques help achieve accurate dimensions, surface finishes, and tight tolerances.

Fixture and Workholding: Securely holding the metal component during machining is crucial to maintain precision. Using appropriate fixtures, clamps, and workholding devices ensures stability and minimizes movement or vibration that could affect the accuracy of the machining process.

Lubrication and Cooling: Proper lubrication and cooling during machining operations help reduce friction, heat buildup, and tool wear. This enhances the accuracy of the machining process and minimizes the potential for thermal distortion or warping of the metal component.

Process Monitoring and Adjustment: Continuously monitoring the manufacturing process and making necessary adjustments is essential for maintaining consistency and precision. This may involve regular measurements, feedback loops, and corrective actions to ensure adherence to specifications.

Skilled Workforce: Having skilled operators and technicians who are experienced in metalworking processes is crucial. Skilled personnel can interpret drawings, operate machinery effectively, troubleshoot issues, and make necessary adjustments to maintain consistency and precision throughout the production process.

Continuous Improvement: Implementing a culture of continuous improvement allows for ongoing refinement of processes, techniques, and equipment. Regular evaluation, analysis of data, and feedback from quality control initiatives can lead to the identification of opportunities for enhancing consistency and precision.

By considering these factors and implementing appropriate measures, manufacturers can achieve consistent and precise metal components that meet the required specifications and quality standards.

TRI VIET MECHANICAL - ELECTRICAL CO., LTD - With the motto: "Adding value together with you" - Tri Viet Electric is pleased to welcome and cooperate with all customers in the future.

Address: III-14 Street No. 13, Tan Binh Industrial Park, Tan Phu District, HCMC

Hotline: 0908.286.507

Email: uttn066@yahoo.com.vn

Website: http://khuondap.vn/

Bài viết khác:

Tìm Hiểu Về Vai Trò Của Chế Tạo Khuôn Dập Trong Đời Sống

Tìm Hiểu Về Nguyên Lý Làm Việc Của Khuôn Dập Liên Hợp

Xưởng Chế Tạo Khuôn Dập Mẫu Chất Lượng

Tìm Hiểu Về Khuôn Dập Liên Hoàn Chất Lượng | Công Ty Cơ Khí Điện Trí Việt

Các bài viết khác

- Đặc Tính Ứng Dụng Của Khuôn Dập Liên Hoàn - Khuôn Dập Liên Tục

- Khuôn Đột Dập

- Công Ty Khuôn Dập Liên Hoàn Theo Yêu Cầu

- Gia Công Sản Phẩm Dập Tấm | Trí Việt

- Khuôn Dập Nguội

- Khuôn Dập Vuốt Là Gì ? Cấu Tạo Và Đặc Điểm

- Nhận Đột Dập Kim Loại Giá Rẻ

- Kinh Nghiệm Thiết Kế Khuôn Dập - Chế Tạo Khuôn Dập

- Khuôn Đột Dập Liên Hoàn Trí Việt

- Thiết Kế, Sản Xuất Và Bảo Trì Khuôn Dập Liên Hoàn