Tin Tức

Tool And Die Manufacturing Company Tri Viet

Tool And Die Manufacturing Company

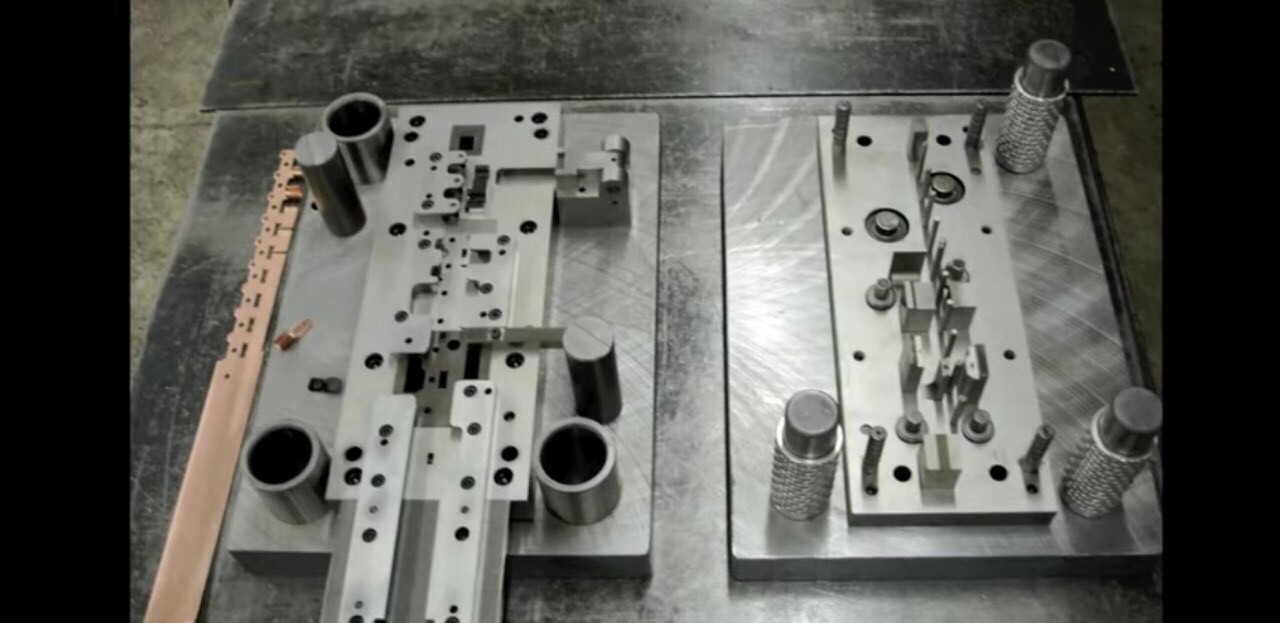

Tool and die manufacturing facilities are integral to the production of various components and parts across industries such as automotive, aerospace, electronics, and more. These facilities are equipped with advanced machinery and specialized equipment to create precise and complex tools and dies used in manufacturing processes.

.jpg)

Tool and Die Manufacturing Facilities

CAD/CAM Software: Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are essential for designing and simulating tool and die components before they are manufactured. These tools help in creating precise and accurate designs, reducing errors, and improving overall efficiency.

CNC Machines: Computer numerical control (CNC) machines are used for precision machining of various materials. CNC milling machines, lathes, and electrical discharge machines (EDMs) are commonly employed to shape and finish parts to exact specifications.

Grinding Machines: Surface and cylindrical grinding machines are used for achieving high precision and smooth finishes on various components, ensuring that the tools and dies meet the required standards and tolerances.

Milling Machines: Milling machines are utilized for cutting and shaping metal and other solid materials to create components with complex shapes and geometries.

Laser Cutting Machines: Laser cutting technology is used to precisely cut and shape various materials, offering high levels of accuracy and enabling the production of intricate and detailed tool and die components.

Quality Control Equipment: Tool and die manufacturing facilities are equipped with various quality control tools, including coordinate measuring machines (CMMs), gauges, and other inspection equipment to ensure that the manufactured components meet the specified requirements and quality standards.

Skilled Workforce: These facilities employ skilled engineers, designers, and machinists who possess expertise in tool and die design, manufacturing, and maintenance. A well-trained workforce is crucial for maintaining the high precision and quality demanded by the industry.

Material Stock and Inventory Management: Efficient material management systems are put in place to ensure the availability of necessary raw materials and components for production. This helps in maintaining a smooth and uninterrupted manufacturing process.

Safety Protocols: Adherence to stringent safety protocols and guidelines is essential in tool and die manufacturing facilities to ensure the safety of the workforce and the proper handling of specialized equipment and machinery.

Tool and die manufacturing facilities play a critical role in supporting various industries by providing the necessary components and tools required for the production of complex and precise parts.

What is a Stamping Die Tri Viet ?

In metal stamping, a male punch forces a piece of sheet metal into a female die with a matching concave shape. The stamping machine applies sufficient pressure until the metal is forced to conform to the die’s shape without the application of heat. Depending on the application, the die may be designed to form or cut the metal or may do both at once.

Stamping dies vary drastically in size and geometry, as they can be used for projects ranging from microelectronics to aerospace components. There are also subtypes of dies used in specific types of stamping. For instance:

Progressive dies are used in progressive stamping, a process in which the component undergoes multiple sequential cutting and bending operations while still attached to a longer metal strip. Like transfer dies, progressive dies are used exclusively in multi-station stamping.

Transfer dies are similar to progressive dies in that they are used for sequential operations in high-volume manufacturing, although transfer stamping does not use a connected metal strip like progressive stamping. The primary difference is that transfer dies are usually used with larger or deep-drawn components, which are transferred in between stations.

Line dies allow for tandem-line stamping of large components and are especially suitable for projects that cannot be manufactured with a single stamping press.

Compound dies are a broad category that encompasses all dies that perform both a cutting and a shaping operation in a single stroke of the die press. Compound dies are an excellent choice for maximizing efficiency.

The best type of stamping die for your project depends on the manufacturing technique and the geometry of your component. Your supplier can help you determine the most suitable option for your needs.

Custom manufacturer of tool and dies for heat transfer coil production and metalworking applications. Types include progressive type tube sheet dies and lines, progressive ribbon type fin dies, and sheet metal blanking, forming and progressive dies, spare tooling, replacement tooling, heat exchanger fin tooling, and prototype tooling. Machinery and fin dies repair, retrofitting and rebuilding services are available. JIT delivery.

TRI VIET MECHANICAL - ELECTRICAL CO., LTD - With the motto: "Adding value together with you" - Tri Viet Electric is pleased to welcome and cooperate with all customers in the future.

Address: III-14 Street No. 13, Tan Binh Industrial Park, Tan Phu District, HCMC

Hotline: 0908.286.507

Email: uttn066@yahoo.com.vn

Website: http://khuondap.vn/

Bài viết khác:

Tìm Hiểu Về Vai Trò Của Chế Tạo Khuôn Dập Trong Đời Sống

Tìm Hiểu Về Nguyên Lý Làm Việc Của Khuôn Dập Liên Hợp

Xưởng Chế Tạo Khuôn Dập Mẫu Chất Lượng

Tìm Hiểu Về Khuôn Dập Liên Hoàn Chất Lượng | Công Ty Cơ Khí Điện Trí Việt

Các bài viết khác

- Đặc Tính Ứng Dụng Của Khuôn Dập Liên Hoàn - Khuôn Dập Liên Tục

- Khuôn Đột Dập

- Công Ty Khuôn Dập Liên Hoàn Theo Yêu Cầu

- Gia Công Sản Phẩm Dập Tấm | Trí Việt

- Khuôn Dập Nguội

- Khuôn Dập Vuốt Là Gì ? Cấu Tạo Và Đặc Điểm

- Nhận Đột Dập Kim Loại Giá Rẻ

- Kinh Nghiệm Thiết Kế Khuôn Dập - Chế Tạo Khuôn Dập

- Khuôn Đột Dập Liên Hoàn Trí Việt

- Thiết Kế, Sản Xuất Và Bảo Trì Khuôn Dập Liên Hoàn